Implementation of the plant floor FIS software and data validation. This web based system tracks daily production counts, system up and down time and real time bottleneck analysis.

MBUSI ASRS Delivery

Contracted to provide hardware design and panel build for the new ASRS delivery and exit conveyors.

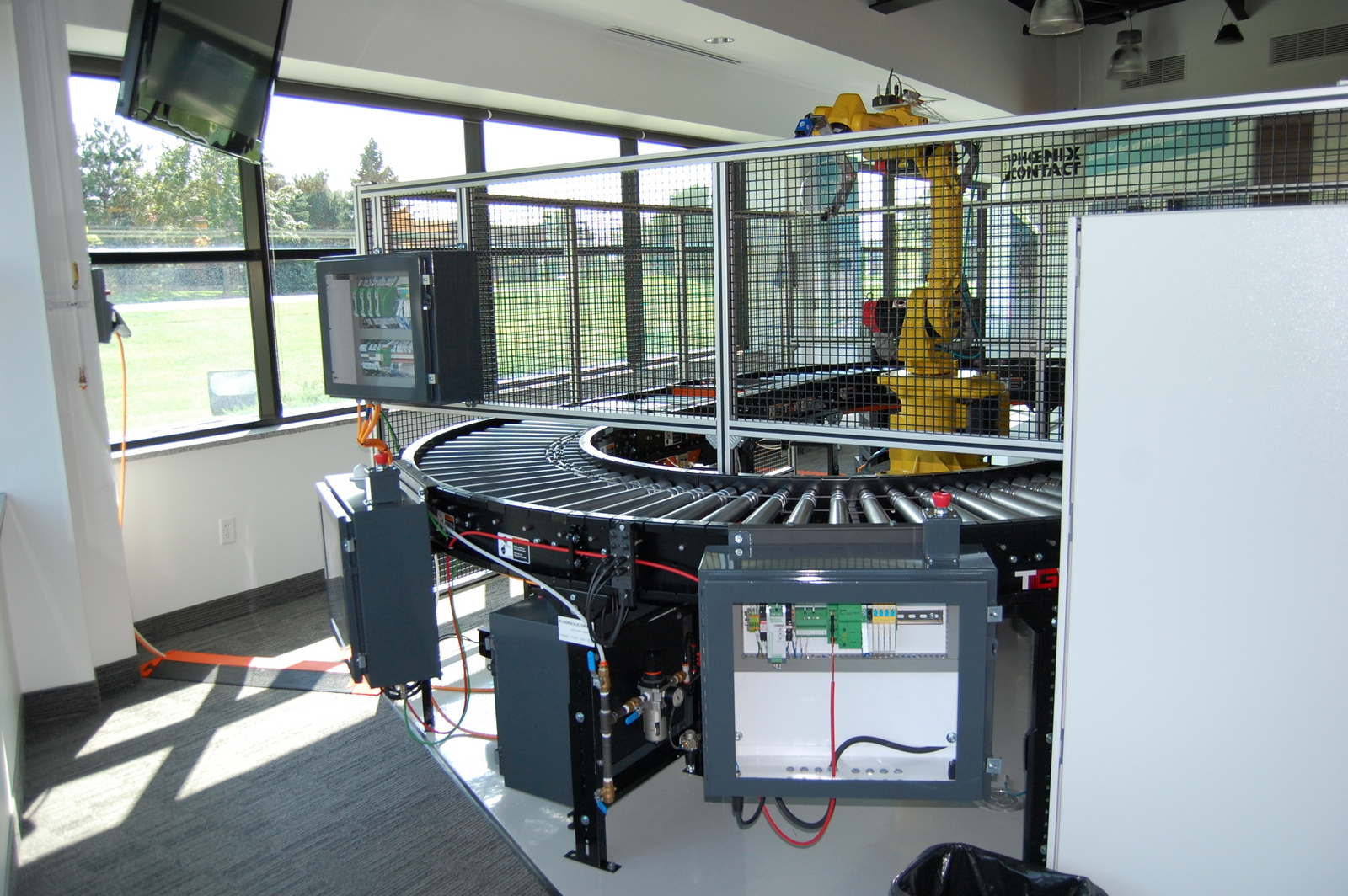

Phoenix Contact Testloop

Provided turnkey controls for Phoenix Contact test conveyor. The solution showcased the latest technology that Phoenix currently produces and is a key exhibit in their training / exhibition center.

Ford LAP Paint Conveyors

Turnkey controls for the paintshop conveyor system utilizing 17 Allen Bradley PLC’s and over 50 Panelview HMI’s. System requirements included Smarteye routing and tracking plus interface to Ford’s FIS system. Additionally new controls for 12 existing air supply house units were also provided.

Nissan Paint Shop

Controls engineering to modify the friction conveyor system in the paintshop.

REQUIREMENTS: Height: 5.2″-6.1″Dress Size: 12-14 These requirements will vary depending on the client.

GM Seat Conveyor Mod’s

Modify existing controls to add additional conveyor sections onto the seat conveyor line to increase capacity. This is a turnkey project that will be completed over Christmas downtime.

Ford Kansas City

Complete controls engineering for the Kansas City paint shop conveyor system. Scope includes hardware & software engineering, control panels and start-up / debug. FIS and AVS are also implemented into the system design. Plant is currently in full production.

MBUSI GA Conveyor Rework

DCS has been awarded a turnkey contract to update the complete control system for the Trim line skillet, final and door line power and free and the wheel line conveyors. All systems will be updated to Mercedes’s latest Integra Wave 4 standards utilizing the latest Siemens Safety PLC equipment. Project is currently in the production trial phase.